Borosilicate Glass Beakers – Technical Specifications

(High-Performance Laboratory Containers)

1. Material Properties

| Characteristic | Boro 3.3 Glass Specification |

|---|---|

| Composition | 81% SiO₂, 13% B₂O₃, 4% Na₂O/K₂O, 2% Al₂O₃ |

| Thermal Shock Resistance | ΔT ≤ 160°C (rapid cooling) |

| Max Operating Temp | 500°C (continuous), 1450°C (short-term) |

| Chemical Resistance | Resists all acids (except HF) and organic solvents |

| Light Transmittance | >95% (400-700 nm visible spectrum) |

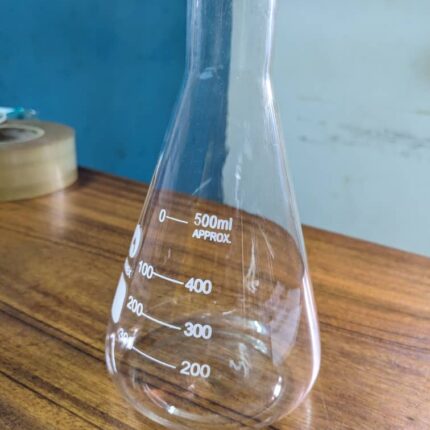

2. Product Line Overview

| Capacity | Height | Diameter | Graduation Interval |

|---|---|---|---|

| 100 mL | 90 mm | 50 mm | 10 mL (“APPROX”) |

| 250 mL | 110 mm | 65 mm | 25 mL |

| 500 mL | 130 mm | 80 mm | 50 mL |

| 1000 mL | 160 mm | 100 mm | 100 mL |

Note: All graduations are approximate (±5% tolerance).

3. Key Features

✔ Spout design: Pouring without drips

✔ Wide base: Enhanced stability

✔ Etched markings: Acid-resistant graduations

✔ Autoclavable: Reusable after sterilization

4. Comparative Advantages

| Property | Borosilicate vs. Soda-Lime Glass |

|---|---|

| Thermal Shock | 3× better resistance |

| Chemical Durability | Withstands concentrated acids |

| Cost | 2-3× higher but longer lifespan |

5. Usage Guidelines

-

Heating: Use wire gauze with ceramic center for even heat distribution

-

Cleaning: Avoid abrasive scrubbers to prevent surface scratches

-

Storage: Stack with protective liners to prevent chipping

Safety Note: Discard if cracks/chips appear – compromised glass may fail under thermal stress.

6. Compliance & Standards

-

Meets ASTM E960 (lab glassware)

-

ISO 4797 (thermal shock testing)

-

CE marked for EU markets

Reviews

There are no reviews yet.