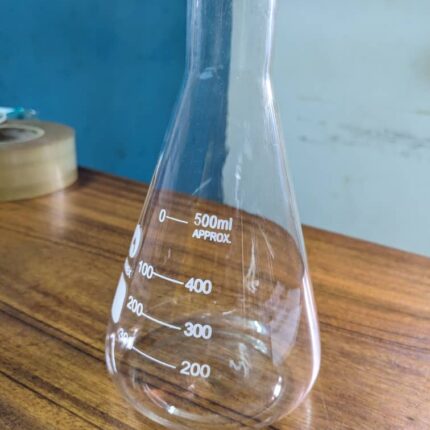

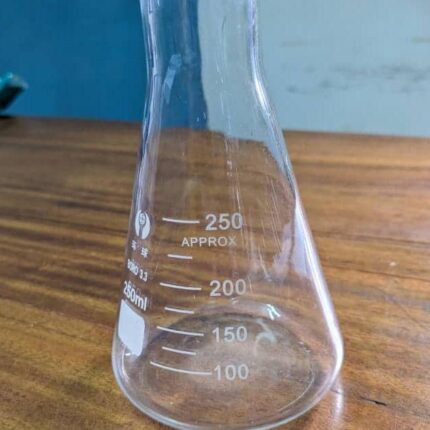

Volumetric Flasks – Technical Specifications

(Precision Liquid Measurement Vessels)

1. Material & Construction

-

Primary Material: Borosilicate glass 3.3 (e.g., Pyrex®)

-

Thermal shock resistant (ΔT ≤ 200°C)

-

Chemical resistance to acids/bases (except HF)

-

-

Stopper: Ground glass joint (NS 29/32 standard)

-

Markings: Permanent enamel graduation

2. Accuracy & Compliance

| Parameter | Class A Specification |

|---|---|

| Tolerance | ±0.08 mL (100 mL flask) |

| Calibration Temp | 20°C ± 0.5°C |

| Standards | DIN EN ISO 1042, ASTM E288 |

| Marking | Engraved “IN” (TC) & “A” grade |

3. Standard Capacities

| Volume | Neck Diameter | Uses |

|---|---|---|

| 50 mL | 14 mm | HPLC standards |

| 100 mL | 16 mm | Titrant prep |

| 250 mL | 22 mm | Molar solutions |

| 500 mL | 28 mm | Bulk reagents |

4. Key Features

✔ Single graduation mark for precise filling

✔ Hexagonal base for stability

✔ Traceable certification (NIST/DKD)

5. Usage Protocol

-

Cleaning: Chromic acid rinse → triple DI water wash

-

Filling: Meniscus tangent to mark (eye-level)

-

Mixing: 10× inversions (no shaking)

Do NOT heat when sealed – thermal expansion risks rupture

6. Quality Verification

-

Weight Test: Verify volume using distilled water (d=0.9982 g/mL at 20°C)

-

Documentation: Class A requires individual calibration certificate

7. Stop:

- It comes with a glass stopper to seal the contents.

8. Compliance:

- Class A volumetric flasks comply with international standards such as DIN EN ISO 1042 and DIN 12664.

Reviews

There are no reviews yet.