Mortar and Pestle

Features of the Laboratory Mortar and Pestle

Mortars and pestles are essential laboratory tools used for grinding and mixing solid substances. Their characteristics are as follows:

Materials: They are generally made of glazed porcelain for high durability and chemical resistance.

Mortar Design:

Shape: The mortar is a bowl-shaped container, spherical, or with a round bottom.

Interior: The interior of the mortar is unglazed or frosted for better grinding efficiency, providing a rough surface that aids in particle size reduction.

Pouring Spout: Equipped with a pouring spout to facilitate the transfer of ground substances.

Pestle Design:

Shape: The pestle is a heavy, blunt object, elongated cylindrical in shape, with a flat or rounded end for grinding.

Material: It is made of the same material as the mortar to ensure optimal compatibility and efficiency.

General Properties:

Chemical Resistance: They must be resistant to commonly used laboratory chemicals to prevent contamination and degradation.

Mechanical and Abrasion Resistance: The materials used must be hard and abrasion-resistant to withstand the grinding of solid substances.

Ease of Cleaning: The surfaces are easy to clean to prevent cross-contamination between experiments.

Applications: They are commonly used in laboratories, pharmaceutical, chemical, and food industries for sample preparation, powder mixing, and grinding solid substances into fine powders.

Dropping Funnel

The dropping funnel, also called an isobaric dropping funnel, is a laboratory instrument made of borosilicate glass (such as LBG 3.3) used for the controlled addition of liquids, usually dropwise.

Its main features are:

Function: It allows the precise and controlled addition of a liquid reactant to a reaction medium, particularly for rapid or exothermic reactions where slow addition is crucial to avoid runaway reactions or explosions.

Isobaric Design: Unlike the separating funnel, the dropping funnel’s stopcock is located higher on the stem, and a thin glass section below the stopcock slows the flow by capillary action, allowing finer flow control.

Material: It is made of borosilicate glass for its resistance to heat and chemicals.

Controlled atmosphere use: It can be used in systems under an inert atmosphere (argon, nitrogen) if the reagent is sensitive to air or moisture.

Variations: It is available in various capacities (50 ml, 250 ml, 500 ml, 1000 ml). It is equipped with a PTFE stopcock for improved sealing and chemical resistance.

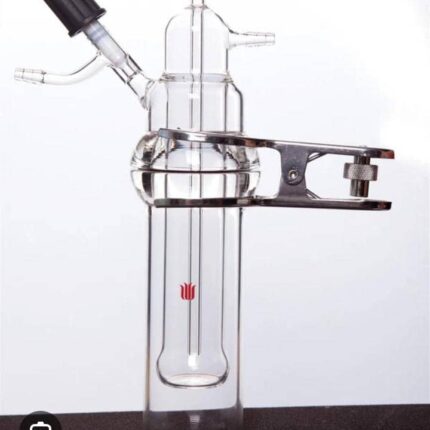

Sublimation Machine

The features of the sublimation machine are as follows:

Type of Machine: Greaseless, two-piece sublimator.

Components: It consists of a water-cooled upper condenser (cold finger) and a lower container to hold the material to be sublimated.

Condenser Design: The condenser is constructed with a greaseless threaded valve. The sublimate collects at the lower end of the condenser, which has a flat bottom.

Connection of Parts: The connection between the condenser and the lower container is made via an O-ring, allowing easy separation for maximum product recovery.

Capacity: The apparatus is available in various capacities, including 100 mL, 250 mL, 500 mL, and 1000 mL.

Materials: The complete apparatus includes the cold-finger condenser, lower vessel, Viton® O-ring, and stainless steel clamp.

Bubbler

A bubbler, also known as a gas washer or Drechsel flask, is a piece of borosilicate glass laboratory equipment designed for washing or drying gases.

Its main features are:

Material: Made of borosilicate glass, it offers excellent resistance to thermal shock and chemical agents.

Design: It consists of a main flask with a standard ground joint, equipped with two glass tubes. One of the tubes immerses the washing liquid, while the other serves as an outlet for the treated gas.

Use: It is used to bubble a gas through a liquid to purify, dry, or react it.

Capacities: Available in various capacities, such as 100 ml, 250 ml, 500 ml, or 1000 ml, depending on the experimental needs.

Weighing Bottle

A weighing bottle, also called a weighing flask.

Its main characteristics are:

Type of laboratory glassware: This is a piece of laboratory equipment commonly used for accurately weighing solids or small quantities of liquids.

Material: Generally made of borosilicate glass (Boro 3.3) for its heat resistance and chemical stability.

Stopper: It is equipped with a ground-in stopper (or milled sealing plug) to ensure a tight seal, preventing the absorption of moisture or carbon dioxide by the reagent and minimizing evaporation.

Dimensions: The numbers “30×50” in the image indicate the dimensions of the bottle, namely 30 mm in diameter and 50 mm in height.

Butyrometer

A Babcock butyrometer, a laboratory instrument used to determine the fat content of milk and dairy products. Its main features are:

Material: Made of high-quality borosilicate glass, conforming to USP Type I and ASTM E438, Type I, Class A requirements.

Graduation: Features a graduated neck with permanent brown markings for direct measurement of fat percentage, e.g., up to 50% for cream or 0.5% in 0.01% increments for skim milk.

Design: Includes a reaction vessel body.

Use: Designed for use in Babcock testing procedures for determining fat content, with a sample size of 18g.

Compliance: Meets specific standards such as ASTM E1043, Type II A, USP Type I, and ASTM E438, Type I, Class A.

Capillary Viscometer

A Cannon-Fenske Opaque Capillary Viscometer.

Its main features are:

Measurement Type: It is designed to measure the kinematic viscosity of transparent and opaque Newtonian liquids.

Conformity to Standards: It is manufactured and used in accordance with international standards such as ASTM D445, ISO 3104, and ASTM D2170.

Design: It is a reverse-flow type U-tube viscometer, allowing the measurement of liquids whose meniscus cannot be easily observed with other types of viscometers.

Sample Volume and Bath Depth: The minimum sample volume required is 12 mL, and the minimum bath depth is 230 mm (9 in).

Calibration: It is supplied with a calibration certificate and an instruction sheet, and both calibrated and uncalibrated versions are available.

Material: It is made of high-quality glass.

Rotating Belt Distillation Column

A rotating belt distillation column is a type of distillation column used for separating liquids with very similar boiling points.

The main features of this equipment are:

Efficient separation: It is designed to separate compounds with very similar boiling points, which is difficult to achieve with simpler distillation columns such as the Vigreux column.

Presence of a rotating belt: Inside the column tube is a rotating device that rotates at high speed. This device creates a thin liquid film and increases the exchange surface area between the liquid and vapor phases, thus improving separation efficiency.

Operating principle: The rotating belt allows for multiple evaporation and condensation cycles along the column, simulating a large number of theoretical plates and allowing for better vapor rectification.

Applications: It is particularly useful in laboratories for the purification of chemicals or the separation of complex mixtures, where high purity is required.

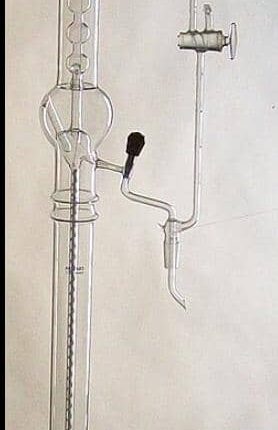

Vigreux Column

Characteristics of a Vigreux Column

The Vigreux column is a piece of laboratory glassware commonly used for fractional distillation. Its main features are as follows:

Internal Structure: It is characterized by the presence of glass spikes or indentations inside the tube, which increase the contact surface between the liquid and vapor phases. These indentations can be horizontal or inclined to optimize vapor-liquid contact and redistribute the liquid.

Distillation Function: These spikes promote successive cycles of vapor condensation and vaporization, thus allowing for more efficient separation of the components of a mixture based on their volatility (fractional distillation).

Material: It is generally made of borosilicate glass, a material known for its good chemical and thermal resistance.

Connections: It may have ground joints (standard conical joints) to facilitate connection to other glassware, such as a distillation flask and condenser.

Integrated distillation head: It incorporates a distillation head with connections for a thermometer, allowing the temperature of the vapors to be measured during distillation.

Number of theoretical plates: The column’s efficiency is characterized by its number of theoretical plates, which is related to the number of vaporization-condensation cycles. The higher this number, the better the separation of the mixture.

Retort

The defining characteristic of a laboratory retort is its specific design for distillation.

Here are its detailed characteristics:

Shape and structure:

It consists of a spherical or pear-shaped vessel intended to contain the substance to be heated.

It has a long, narrow, downward-curving neck, which serves as a condenser and conduit for the distillate.

Material: It is made of glass, blown glass.

Function: Its main purpose is distillation, allowing substances to be separated by heating and condensation of vapors. The distillate flows down the neck to be collected in another container.

History: The retort is an ancient instrument, widely used by alchemists and early chemists for distillation, before the advent of modern refrigerants.

Crystallizing Dish

The borosilicate glass crystallizing dish has the following characteristics:

Material: Made of borosilicate glass 3.3, it offers high resistance to temperature and thermal shock.

Shape and Design: It is a shallow, flat-bottomed cylindrical container with a pouring spout for easy transfer of liquids.

Use: Ideal for evaporative crystallization in the laboratory.

Resistance: It is resistant to cold alkaline solutions and strong acids (except hydrofluoric acid and concentrated hot phosphoric acid).

Sterilization: It can be sterilized in an autoclave, withstanding high temperatures (up to 500°C).

Stability: Its wide base ensures good stability.

Other Features: It features high purity (SiO2 >99.99%), good light transmission, and excellent thermal shock stability.

Cuvette (analysis)

A spectrophotometric cuvette, specifically a quartz cuvette suitable for UV analysis (as indicated by the designation “UV -6030-“).

A cuvette is a small, transparent container, usually square or rectangular, used in laboratories to hold samples (most often liquids) during spectroscopic analyses, such as spectrophotometry, fluorimetry, or colorimetry.

Characteristics and Uses:

Material: Cuvettes are made of glass. Cuvettes are suitable for analyses in the ultraviolet (UV) region, in addition to the visible and infrared, thanks to their wide spectral transmission range.

Function: They measure the absorbance or transmission of light through a sample, providing information about its concentration or composition.

Path Lengths: They are available with different optical path lengths.