Test Tubes 25 ml

The characteristics of a test tube like the one pictured include the following:

Materials:

Clear glass (such as soda-lime glass or borosilicate).

Shape:

A narrow cylindrical body with a base that can be round (U-shaped), conical (V-shaped), or flat, and a top opening. The image shows a flat bottom.

Dimensions and Capacity:

Test tubes come in various sizes and volumes. The one pictured is graduated up to 25 ml, with an accuracy indication of “±0.2”. The visible graduations are 5, 10, 15, 20, and 25 ml.

Use:

Used in laboratories to hold, mix, and heat chemicals, or for specific analyses such as food quality control or blood tests. The object in the image, being graduated, is more specifically a flask, used to precisely measure liquid volumes.

Resistance:

Resistance to temperature changes and chemicals varies depending on the type of glass.

Graduated Pipette

The characteristics of these graduated pipettes are as follows:

Brand and Volume:

This is a Citotest brand graduated pipette, with a maximum volume of 50 ml.

Materials:

It is made of glass, as suggested by its transparency and common laboratory use for this type of instrument.

Graduations:

The pipette features clear and precise graduations, allowing for accurate measurement of liquids.

Conformity:

Graduated pipettes of this type comply with the accuracy standards for laboratory volumetric instruments, such as the ISO 6706 Class B standard for graduated cylinders mentioned for similar Citotest products.

Use:

It is designed for transferring and measuring precise volumes of liquids in the laboratory, particularly for liquid handling.

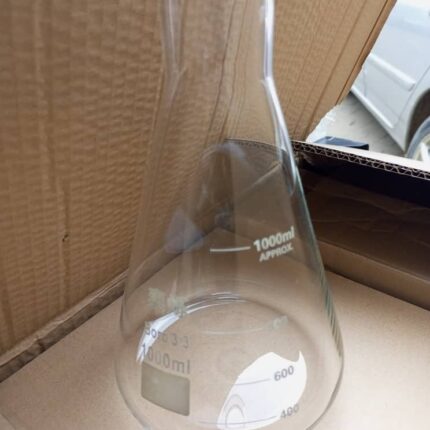

Erlenmeyer flask 1000 ml

A borosilicate glass Erlenmeyer flask has several key characteristics:

Materials:

It is made of borosilicate 3.3 glass (such as Pyrex™ or Duran®), known for its high resistance to thermal shock and chemical corrosion.

Capacity:

The flask pictured has a capacity of 1000 ml, with graduations indicating volumes (e.g., 400 ml, 600 ml).

Shape:

Its conical shape ensures good stability and facilitates mixing and heating liquids. The neck can be narrow or wide.

Graduations:

It has graduations (often white enamel) for approximate volume measurements.

Resistance:

Borosilicate glass provides excellent heat resistance, allowing direct heating and autoclaving for sterilization.

Use:

It is commonly used in laboratories for mixing, heating, cooling, and storing liquids, as well as for titrations and cell cultures.

Separating Funnel

The separating funnel has the following characteristics:

Shape:

It is pear-shaped (or conical), optimized for phase separation.

Materials:

Made of borosilicate glass, which gives it chemical resistance and inertness.

Capacity:

The marking on the funnel indicates a capacity of 500 mL.

Stopcock:

It is equipped with a PTFE (polytetrafluoroethylene) stopcock, known for its chemical resistance and leak-tightness. The stopcock allows precise control of liquid flow.

Ground Joint:

The upper neck has a 24/29 type ground joint, indicating compatibility with stoppers or other laboratory equipment of the corresponding size.

Conformity:

This type of funnel complies with international standards such as ISO 4800.

Glass Funnel

Glass laboratory funnel. Its main characteristics are as follows:

Material:

Made of borosilicate glass, known for its resistance to saline solutions, acids, bases, and organic solvents, as well as thermal shock.

Construction:

It consists of a flared conical portion for easy pouring and a tubular stem to direct the flow into a narrow-mouthed container.

Use:

Mainly used for transferring liquids or powders into narrow-mouthed containers without spilling, and can also be used as a filter paper holder during gravity filtration.

Dimensions:

Glass funnels are available in various sizes, namely: 90mm, 120mm, with varying stem diameters and lengths, suitable for various laboratory applications.

Standards:

Manufactured according to specific standards such as ISO 4798 or DIN 12445 to ensure quality and laboratory compatibility.

Glass Beaker

Borosilicate Glass Beakers – Technical Specifications

(High-Performance Laboratory Containers)

1. Material Properties

| Characteristic | Boro 3.3 Glass Specification |

|---|---|

| Composition | 81% SiO₂, 13% B₂O₃, 4% Na₂O/K₂O, 2% Al₂O₃ |

| Thermal Shock Resistance | ΔT ≤ 160°C (rapid cooling) |

| Max Operating Temp | 500°C (continuous), 1450°C (short-term) |

| Chemical Resistance | Resists all acids (except HF) and organic solvents |

| Light Transmittance | >95% (400-700 nm visible spectrum) |

2. Product Line Overview

| Capacity | Height | Diameter | Graduation Interval |

|---|---|---|---|

| 100 mL | 90 mm | 50 mm | 10 mL (“APPROX”) |

| 250 mL | 110 mm | 65 mm | 25 mL |

| 500 mL | 130 mm | 80 mm | 50 mL |

| 1000 mL | 160 mm | 100 mm | 100 mL |

Note: All graduations are approximate (±5% tolerance).

3. Key Features

✔ Spout design: Pouring without drips

✔ Wide base: Enhanced stability

✔ Etched markings: Acid-resistant graduations

✔ Autoclavable: Reusable after sterilization

4. Comparative Advantages

| Property | Borosilicate vs. Soda-Lime Glass |

|---|---|

| Thermal Shock | 3× better resistance |

| Chemical Durability | Withstands concentrated acids |

| Cost | 2-3× higher but longer lifespan |

5. Usage Guidelines

-

Heating: Use wire gauze with ceramic center for even heat distribution

-

Cleaning: Avoid abrasive scrubbers to prevent surface scratches

-

Storage: Stack with protective liners to prevent chipping

Safety Note: Discard if cracks/chips appear – compromised glass may fail under thermal stress.

6. Compliance & Standards

-

Meets ASTM E960 (lab glassware)

-

ISO 4797 (thermal shock testing)

-

CE marked for EU markets

Volumetric Flask

Volumetric Flasks – Technical Specifications

(Precision Liquid Measurement Vessels)

1. Material & Construction

-

Primary Material: Borosilicate glass 3.3 (e.g., Pyrex®)

-

Thermal shock resistant (ΔT ≤ 200°C)

-

Chemical resistance to acids/bases (except HF)

-

-

Stopper: Ground glass joint (NS 29/32 standard)

-

Markings: Permanent enamel graduation

2. Accuracy & Compliance

| Parameter | Class A Specification |

|---|---|

| Tolerance | ±0.08 mL (100 mL flask) |

| Calibration Temp | 20°C ± 0.5°C |

| Standards | DIN EN ISO 1042, ASTM E288 |

| Marking | Engraved “IN” (TC) & “A” grade |

3. Standard Capacities

| Volume | Neck Diameter | Uses |

|---|---|---|

| 50 mL | 14 mm | HPLC standards |

| 100 mL | 16 mm | Titrant prep |

| 250 mL | 22 mm | Molar solutions |

| 500 mL | 28 mm | Bulk reagents |

4. Key Features

✔ Single graduation mark for precise filling

✔ Hexagonal base for stability

✔ Traceable certification (NIST/DKD)

5. Usage Protocol

-

Cleaning: Chromic acid rinse → triple DI water wash

-

Filling: Meniscus tangent to mark (eye-level)

-

Mixing: 10× inversions (no shaking)

Do NOT heat when sealed – thermal expansion risks rupture

6. Quality Verification

-

Weight Test: Verify volume using distilled water (d=0.9982 g/mL at 20°C)

-

Documentation: Class A requires individual calibration certificate

Burettes

Burettes – Precision Liquid Dispensing Instruments

(For Titrations & Volumetric Analysis)

1. Key Components

| Part | Description |

|---|---|

| Graduated Tube | Long cylindrical glass with precision markings (Class A/B tolerance) |

| Stopcock | PTFE or glass valve for flow control |

| Tip | Tapered delivery end for drop-wise dispensing |

| Mounting Clamp | For secure positioning on stands |

2. Technical Specifications

| Parameter | Details |

|---|---|

| Standard Volumes | 10 mL, 25 mL, 50 mL (Also available: 5 mL, 100 mL) |

| Graduation | 0.1 mL increments (50 mL) |

| Accuracy | ±0.05 mL (Class A) |

| Meniscus Reading | Bottom (clear liquids) / Top (dark solutions) |

| Material | Borosilicate glass (3.3) |

3. Types & Selection Guide

-

Digital Burettes: Motorized, programmable dispensing

-

Microburettes: For <1 mL volumes (0.01 mL gradations)

-

Automatic Zeroing: Self-refilling designs

4. Proper Usage Protocol

-

Rinsing: Pre-wet with titrant solution

-

Filling: Avoid air bubbles (use funnel)

-

Reading: Eye level at meniscus

-

Delivery: Slow, drop-wise near endpoint

5. Calibration & Maintenance

-

Verification: Annual calibration with distilled water

-

Cleaning: Chromic acid for stubborn residues

-

Storage: Vertical position, stopcock grease applied

D-Mannitol

D-Mannitol Technical Specifications

*(C₆H₁₄O₆ | CAS No.: 69-65-8 | EC No.: 200-711-8)*

1. Fundamental Properties

| Parameter | Specification |

|---|---|

| Molecular Weight | 182.17 g/mol |

| Appearance | White crystalline powder |

| Melting Point | 167-170°C |

| Solubility | 213 g/L in water (20°C) |

| pH (10% sol.) | 5.0-7.0 |

| Sweetness | 70% of sucrose |

2. Key Applications

A. Pharmaceutical

-

Osmotic diuretic: Reduces intracranial/intraocular pressure

-

Excipient: Tablet filler (direct compression), lyophilization stabilizer

-

Diagnostic agent: Renal function tests

B. Food Industry

-

Low-calorie sweetener (E421)

-

Anti-caking agent in chewing gums/sweets

-

Sugar-free product formulations

C. Microbiology

-

Carbon source in culture media (e.g., Mannitol Salt Agar)

-

Fermentation studies

3. Safety & Handling

| Aspect | Detail |

|---|---|

| Glycemic Index | Low (GI=0) |

| Storage | ≤25°C, dry environment |

| Explosion Risk | Dust-air mixtures may be combustible |

| Regulatory Status | GRAS (FDA), EFSA-approved |

4. Quality Standards

-

Purity: ≥98% (HPLC)

-

Residues: Heavy metals ≤10 ppm

-

Microbial Limits: TAMC <100 CFU/g

5. Comparative Advantages

✔ Renal-safe diuretic (minimal tubular reabsorption)

✔ Tooth-friendly sweetener (non-cariogenic)

✔ High chemical stability in formulations

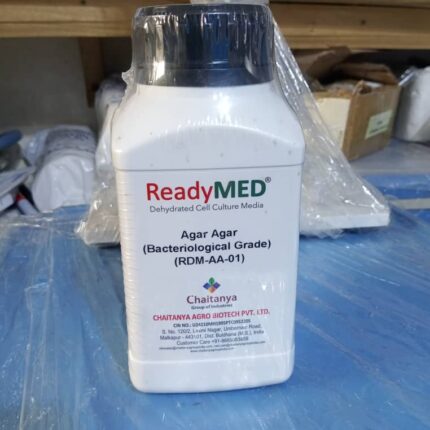

Agar Agar

ReadyMED™ Agar Agar (Bacteriological Grade) – RDM-AA-01

High-Purity Gelling Agent for Microbiological Culture Media

Manufactured by Chaitanya Agro Biotech Pvt. Ltd.

1. Product Overview

-

Form: White to off-white dehydrated powder

-

Grade: Bacteriological (Low DNase/Rnase activity)

-

Gel Strength: ≥1200 g/cm² (1.5% gel at 25°C)

-

Product Code: RDM-AA-01

2. Key Properties

| Parameter | Specification |

|---|---|

| Ash Content | ≤2.5% |

| Gelling Temp | 32-39°C |

| Melting Temp | 85-95°C |

| Microbial Load | ≤100 CFU/g |

| pH (1.5% sol.) | 6.5-7.5 |

3. Functional Applications

-

Base component for:

-

Selective media (e.g., MacConkey, MSA)

-

Differential media (e.g., EMB, XLD)

-

General-purpose media (e.g., Nutrient Agar)

-

-

Typical Use Concentration: 1-2% w/v

4. Technical Advantages

✔ Consistent gelling properties for reproducible media

✔ Low mineral content minimizes interference with selectivity

✔ Optimal clarity for colony morphology observation

5. Storage & Handling

-

Storage: 10-30°C in airtight container (RH <50%)

-

Shelf Life: 5 years from manufacture

-

Safety: Non-toxic; autoclave contaminated material before disposal

6. Preparation Guidelines

-

Suspension: Slowly sprinkle into heated (80-90°C) distilled water while stirring

-

Dissolution: Boil 1 minute to ensure complete hydration

-

Autoclaving: 121°C for 15 minutes (for most applications)

7. Quality Compliance

-

Meets USP/EP/JP standards for microbiological media

-

Batch-specific Certificate of Analysis available

Nutrient Agar

L:S-BIOTECH Nutrient Agar (IVD Grade)

General-Purpose Microbiological Culture Medium

Manufactured/Distributed by LIFESAVE BIOTECH

1. Product Identification

-

Product Name: Nutrient Agar

-

Brand: L:S-BIOTECH

-

Classification:

-

Laboratory reagent (“MORATORY REAGENTS” label)

-

IVD In Vitro Diagnostics (CE marked if applicable)

-

-

Intended Use: Cultivation of non-fastidious microorganisms

2. Key Features

-

General-purpose medium for routine bacteriology

-

IVD-compliant formulation for diagnostic use

-

Standard composition:

-

Peptones (nitrogen source)

-

Beef extract (growth factors)

-

Sodium chloride (osmotic balance)

-

Agar (solidifying agent)

-

-

Typical pH: 7.4 ± 0.2

3. Applications

✔ Quality control testing

✔ Environmental monitoring

✔ Educational demonstrations

✔ Primary isolation of non-fastidious:

-

Bacteria

-

Yeasts

-

Molds

4. Compliance & Safety

-

For In Vitro Use Only (Not for human/animal administration)

-

Manufactured under ISO 13485 (if IVD-certified)

-

Standard shelf life: 3 years when stored sealed at 15-30°C

5. Preparation Protocol

-

Suspend 28g per 1L distilled water

-

Autoclave at 121°C for 15 minutes

-

Pour into sterile Petri dishes

6. Performance Characteristics

-

Growth Promotion: Supports growth of:

-

E. coli ATCC 25922

-

S. aureus ATCC 25923

-

-

Sterility: No contamination after incubation

7. Ordering Information

Manufacturer: LIFESAVE BIOTECH

Packaging: Typically 500g bottles

Storage: Room temperature (dry)

Müller Hinton Agar

ReadyMED™ Mueller Hinton Agar (RDM-MHA-01)

Standardized Medium for Antimicrobial Susceptibility Testing

Manufactured by Chaitanya Agro Biotech Pvt. Ltd. (Buldhana, Maharashtra, India)

1. Product Overview

-

Form: White biotech-grade dehydrated powder

-

Packaging: 1 kg bottles

-

Storage: 2-8°C (until expiration date)

-

Purity: ≥95%

2. Key Applications

-

Kirby-Bauer disk diffusion testing

-

Broth microdilution assays

-

Standardized AST for non-fastidious pathogens

3. Composition & Performance

| Component | Function | Concentration |

|---|---|---|

| Beef extract | Nutrient source | 2.0 g/L |

| Acid hydrolysate of casein | Amino acids | 17.5 g/L |

| Starch | Absorbs toxins | 1.5 g/L |

| Agar | Solidifying agent | 17.0 g/L |

Critical Properties:

-

Low levels of sulfonamide/trimethoprim inhibitors

-

pH 7.3 ± 0.1 (after solidification)

-

4mm depth compliance for disk diffusion

4. Quality Assurance

-

Batch-to-batch consistency for reproducible zone sizes

-

Validated with reference strains:

-

E. coli ATCC 25922

-

S. aureus ATCC 29213

-

P. aeruginosa ATCC 27853

-

-

Meets CLSI/EUCAST standards

5. Preparation Protocol

-

Suspension: 38g per 1L distilled water

-

Heating: Boil with stirring (100°C, 1 min)

-

Sterilization: Autoclave (121°C, 15 min)

-

Pouring: 25mL per 90mm plate (4mm depth)

-

QC Testing: Verify with control strains

6. Manufacturer Credentials

-

Parent Company: Chaitanya Group

-

Facility: cGMP-compliant production

-

Regulatory Status: IVD-grade (CE marked if applicable)

7. Why Choose ReadyMED MHA?

✔ CLSI-compliant formulation

✔ Optimized for accurate zone edge definition

✔ Traceable raw materials

✔ Long shelf life (typically 3 years)

Product Code: RDM-MHA-01