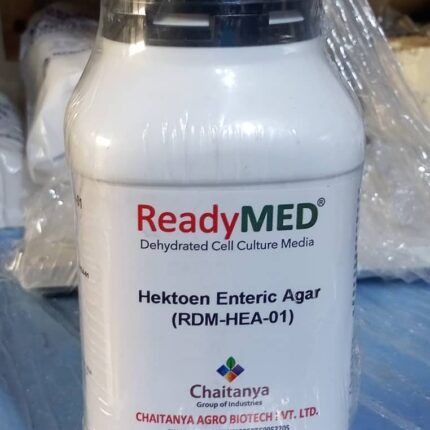

Hektoen Enteric Agar

Hektoen Enteric Agar (HEA) – Technical Specifications

Selective & Differential Medium for Enteric Pathogens

1. Intended Use

-

Primary Application: Isolation/differentiation of Salmonella and Shigella spp.

-

Sample Types: Clinical stool specimens, food, environmental samples

2. Key Functional Components

| Component | Role |

|---|---|

| Bile salts | Inhibits Gram-positive & non-pathogenic Gram-negative bacteria |

| Lactose/sucrose/salicin | Carbohydrate sources for fermentation |

| Sodium thiosulfate + Ferric ammonium citrate | H₂S production detection |

| Bromothymol blue + Acid fuchsin | pH indicators (differentiate fermenters) |

3. Physical Characteristics

-

Color: Green (prepared medium)

-

Clarity: Clear to slightly opalescent

-

pH: 7.5 ± 0.2 at 25°C

-

Format: Dehydrated powder

Performance Characteristics

Colony Morphology

| Organism | Colony Appearance | Biochemical Basis |

|---|---|---|

| E. coli (coliform) | Salmon-pink, may yellow medium | Rapid lactose fermentation |

| Salmonella spp. | Blue-green with black centers | H₂S production (thiosulfate → FeS) |

| Shigella spp. | Pale green, translucent | Non-lactose fermenter |

| Proteus spp. | Colorless with blackening | H₂S production only |

Quality Control Parameters

-

Sterility: No growth after 24h at 35°C

-

Growth Promotion:

-

Salmonella enterica ATCC 14028: Blue-green colonies with H₂S

-

Shigella flexneri ATCC 12022: Pale green colonies

-

-

Selectivity: ≥80% inhibition of E. coli ATCC 25922

Protocol Summary

-

Preparation: Suspend 75g/L, boil to dissolve, autoclave (121°C, 15 min)

-

Plating: Pour into Petri dishes (~20mL/plate)

-

Inoculation: Streak for isolation

-

Incubation: 35-37°C for 18-24h (extend to 48h for low-density samples)

Regulatory & Storage

-

Shelf Life: 3 years (unopened, <30°C)

-

Safety: Handle as potential biohazard post-inoculation

Advantages Over Competing Media

✔ Dual differentiation (fermentation + H₂S)

✔ Superior Shigella recovery vs. SS Agar

✔ Color contrast enhances readability

Müller Hinton Agar

ReadyMED™ Mueller Hinton Agar (RDM-MHA-01)

Standardized Medium for Antimicrobial Susceptibility Testing

Manufactured by Chaitanya Agro Biotech Pvt. Ltd. (Buldhana, Maharashtra, India)

1. Product Overview

-

Form: White biotech-grade dehydrated powder

-

Packaging: 1 kg bottles

-

Storage: 2-8°C (until expiration date)

-

Purity: ≥95%

2. Key Applications

-

Kirby-Bauer disk diffusion testing

-

Broth microdilution assays

-

Standardized AST for non-fastidious pathogens

3. Composition & Performance

| Component | Function | Concentration |

|---|---|---|

| Beef extract | Nutrient source | 2.0 g/L |

| Acid hydrolysate of casein | Amino acids | 17.5 g/L |

| Starch | Absorbs toxins | 1.5 g/L |

| Agar | Solidifying agent | 17.0 g/L |

Critical Properties:

-

Low levels of sulfonamide/trimethoprim inhibitors

-

pH 7.3 ± 0.1 (after solidification)

-

4mm depth compliance for disk diffusion

4. Quality Assurance

-

Batch-to-batch consistency for reproducible zone sizes

-

Validated with reference strains:

-

E. coli ATCC 25922

-

S. aureus ATCC 29213

-

P. aeruginosa ATCC 27853

-

-

Meets CLSI/EUCAST standards

5. Preparation Protocol

-

Suspension: 38g per 1L distilled water

-

Heating: Boil with stirring (100°C, 1 min)

-

Sterilization: Autoclave (121°C, 15 min)

-

Pouring: 25mL per 90mm plate (4mm depth)

-

QC Testing: Verify with control strains

6. Manufacturer Credentials

-

Parent Company: Chaitanya Group

-

Facility: cGMP-compliant production

-

Regulatory Status: IVD-grade (CE marked if applicable)

7. Why Choose ReadyMED MHA?

✔ CLSI-compliant formulation

✔ Optimized for accurate zone edge definition

✔ Traceable raw materials

✔ Long shelf life (typically 3 years)

Product Code: RDM-MHA-01

Nutrient Agar

L:S-BIOTECH Nutrient Agar (IVD Grade)

General-Purpose Microbiological Culture Medium

Manufactured/Distributed by LIFESAVE BIOTECH

1. Product Identification

-

Product Name: Nutrient Agar

-

Brand: L:S-BIOTECH

-

Classification:

-

Laboratory reagent (“MORATORY REAGENTS” label)

-

IVD In Vitro Diagnostics (CE marked if applicable)

-

-

Intended Use: Cultivation of non-fastidious microorganisms

2. Key Features

-

General-purpose medium for routine bacteriology

-

IVD-compliant formulation for diagnostic use

-

Standard composition:

-

Peptones (nitrogen source)

-

Beef extract (growth factors)

-

Sodium chloride (osmotic balance)

-

Agar (solidifying agent)

-

-

Typical pH: 7.4 ± 0.2

3. Applications

✔ Quality control testing

✔ Environmental monitoring

✔ Educational demonstrations

✔ Primary isolation of non-fastidious:

-

Bacteria

-

Yeasts

-

Molds

4. Compliance & Safety

-

For In Vitro Use Only (Not for human/animal administration)

-

Manufactured under ISO 13485 (if IVD-certified)

-

Standard shelf life: 3 years when stored sealed at 15-30°C

5. Preparation Protocol

-

Suspend 28g per 1L distilled water

-

Autoclave at 121°C for 15 minutes

-

Pour into sterile Petri dishes

6. Performance Characteristics

-

Growth Promotion: Supports growth of:

-

E. coli ATCC 25922

-

S. aureus ATCC 25923

-

-

Sterility: No contamination after incubation

7. Ordering Information

Manufacturer: LIFESAVE BIOTECH

Packaging: Typically 500g bottles

Storage: Room temperature (dry)

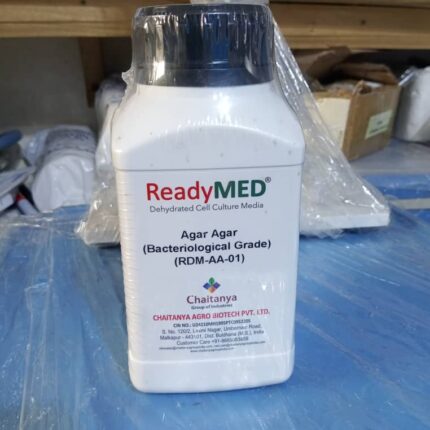

Agar Agar

ReadyMED™ Agar Agar (Bacteriological Grade) – RDM-AA-01

High-Purity Gelling Agent for Microbiological Culture Media

Manufactured by Chaitanya Agro Biotech Pvt. Ltd.

1. Product Overview

-

Form: White to off-white dehydrated powder

-

Grade: Bacteriological (Low DNase/Rnase activity)

-

Gel Strength: ≥1200 g/cm² (1.5% gel at 25°C)

-

Product Code: RDM-AA-01

2. Key Properties

| Parameter | Specification |

|---|---|

| Ash Content | ≤2.5% |

| Gelling Temp | 32-39°C |

| Melting Temp | 85-95°C |

| Microbial Load | ≤100 CFU/g |

| pH (1.5% sol.) | 6.5-7.5 |

3. Functional Applications

-

Base component for:

-

Selective media (e.g., MacConkey, MSA)

-

Differential media (e.g., EMB, XLD)

-

General-purpose media (e.g., Nutrient Agar)

-

-

Typical Use Concentration: 1-2% w/v

4. Technical Advantages

✔ Consistent gelling properties for reproducible media

✔ Low mineral content minimizes interference with selectivity

✔ Optimal clarity for colony morphology observation

5. Storage & Handling

-

Storage: 10-30°C in airtight container (RH <50%)

-

Shelf Life: 5 years from manufacture

-

Safety: Non-toxic; autoclave contaminated material before disposal

6. Preparation Guidelines

-

Suspension: Slowly sprinkle into heated (80-90°C) distilled water while stirring

-

Dissolution: Boil 1 minute to ensure complete hydration

-

Autoclaving: 121°C for 15 minutes (for most applications)

7. Quality Compliance

-

Meets USP/EP/JP standards for microbiological media

-

Batch-specific Certificate of Analysis available

D-Mannitol

D-Mannitol Technical Specifications

*(C₆H₁₄O₆ | CAS No.: 69-65-8 | EC No.: 200-711-8)*

1. Fundamental Properties

| Parameter | Specification |

|---|---|

| Molecular Weight | 182.17 g/mol |

| Appearance | White crystalline powder |

| Melting Point | 167-170°C |

| Solubility | 213 g/L in water (20°C) |

| pH (10% sol.) | 5.0-7.0 |

| Sweetness | 70% of sucrose |

2. Key Applications

A. Pharmaceutical

-

Osmotic diuretic: Reduces intracranial/intraocular pressure

-

Excipient: Tablet filler (direct compression), lyophilization stabilizer

-

Diagnostic agent: Renal function tests

B. Food Industry

-

Low-calorie sweetener (E421)

-

Anti-caking agent in chewing gums/sweets

-

Sugar-free product formulations

C. Microbiology

-

Carbon source in culture media (e.g., Mannitol Salt Agar)

-

Fermentation studies

3. Safety & Handling

| Aspect | Detail |

|---|---|

| Glycemic Index | Low (GI=0) |

| Storage | ≤25°C, dry environment |

| Explosion Risk | Dust-air mixtures may be combustible |

| Regulatory Status | GRAS (FDA), EFSA-approved |

4. Quality Standards

-

Purity: ≥98% (HPLC)

-

Residues: Heavy metals ≤10 ppm

-

Microbial Limits: TAMC <100 CFU/g

5. Comparative Advantages

✔ Renal-safe diuretic (minimal tubular reabsorption)

✔ Tooth-friendly sweetener (non-cariogenic)

✔ High chemical stability in formulations

Burettes

Burettes – Precision Liquid Dispensing Instruments

(For Titrations & Volumetric Analysis)

1. Key Components

| Part | Description |

|---|---|

| Graduated Tube | Long cylindrical glass with precision markings (Class A/B tolerance) |

| Stopcock | PTFE or glass valve for flow control |

| Tip | Tapered delivery end for drop-wise dispensing |

| Mounting Clamp | For secure positioning on stands |

2. Technical Specifications

| Parameter | Details |

|---|---|

| Standard Volumes | 10 mL, 25 mL, 50 mL (Also available: 5 mL, 100 mL) |

| Graduation | 0.1 mL increments (50 mL) |

| Accuracy | ±0.05 mL (Class A) |

| Meniscus Reading | Bottom (clear liquids) / Top (dark solutions) |

| Material | Borosilicate glass (3.3) |

3. Types & Selection Guide

-

Digital Burettes: Motorized, programmable dispensing

-

Microburettes: For <1 mL volumes (0.01 mL gradations)

-

Automatic Zeroing: Self-refilling designs

4. Proper Usage Protocol

-

Rinsing: Pre-wet with titrant solution

-

Filling: Avoid air bubbles (use funnel)

-

Reading: Eye level at meniscus

-

Delivery: Slow, drop-wise near endpoint

5. Calibration & Maintenance

-

Verification: Annual calibration with distilled water

-

Cleaning: Chromic acid for stubborn residues

-

Storage: Vertical position, stopcock grease applied

Volumetric Flask

Volumetric Flasks – Technical Specifications

(Precision Liquid Measurement Vessels)

1. Material & Construction

-

Primary Material: Borosilicate glass 3.3 (e.g., Pyrex®)

-

Thermal shock resistant (ΔT ≤ 200°C)

-

Chemical resistance to acids/bases (except HF)

-

-

Stopper: Ground glass joint (NS 29/32 standard)

-

Markings: Permanent enamel graduation

2. Accuracy & Compliance

| Parameter | Class A Specification |

|---|---|

| Tolerance | ±0.08 mL (100 mL flask) |

| Calibration Temp | 20°C ± 0.5°C |

| Standards | DIN EN ISO 1042, ASTM E288 |

| Marking | Engraved “IN” (TC) & “A” grade |

3. Standard Capacities

| Volume | Neck Diameter | Uses |

|---|---|---|

| 50 mL | 14 mm | HPLC standards |

| 100 mL | 16 mm | Titrant prep |

| 250 mL | 22 mm | Molar solutions |

| 500 mL | 28 mm | Bulk reagents |

4. Key Features

✔ Single graduation mark for precise filling

✔ Hexagonal base for stability

✔ Traceable certification (NIST/DKD)

5. Usage Protocol

-

Cleaning: Chromic acid rinse → triple DI water wash

-

Filling: Meniscus tangent to mark (eye-level)

-

Mixing: 10× inversions (no shaking)

Do NOT heat when sealed – thermal expansion risks rupture

6. Quality Verification

-

Weight Test: Verify volume using distilled water (d=0.9982 g/mL at 20°C)

-

Documentation: Class A requires individual calibration certificate

Glass Beaker

Borosilicate Glass Beakers – Technical Specifications

(High-Performance Laboratory Containers)

1. Material Properties

| Characteristic | Boro 3.3 Glass Specification |

|---|---|

| Composition | 81% SiO₂, 13% B₂O₃, 4% Na₂O/K₂O, 2% Al₂O₃ |

| Thermal Shock Resistance | ΔT ≤ 160°C (rapid cooling) |

| Max Operating Temp | 500°C (continuous), 1450°C (short-term) |

| Chemical Resistance | Resists all acids (except HF) and organic solvents |

| Light Transmittance | >95% (400-700 nm visible spectrum) |

2. Product Line Overview

| Capacity | Height | Diameter | Graduation Interval |

|---|---|---|---|

| 100 mL | 90 mm | 50 mm | 10 mL (“APPROX”) |

| 250 mL | 110 mm | 65 mm | 25 mL |

| 500 mL | 130 mm | 80 mm | 50 mL |

| 1000 mL | 160 mm | 100 mm | 100 mL |

Note: All graduations are approximate (±5% tolerance).

3. Key Features

✔ Spout design: Pouring without drips

✔ Wide base: Enhanced stability

✔ Etched markings: Acid-resistant graduations

✔ Autoclavable: Reusable after sterilization

4. Comparative Advantages

| Property | Borosilicate vs. Soda-Lime Glass |

|---|---|

| Thermal Shock | 3× better resistance |

| Chemical Durability | Withstands concentrated acids |

| Cost | 2-3× higher but longer lifespan |

5. Usage Guidelines

-

Heating: Use wire gauze with ceramic center for even heat distribution

-

Cleaning: Avoid abrasive scrubbers to prevent surface scratches

-

Storage: Stack with protective liners to prevent chipping

Safety Note: Discard if cracks/chips appear – compromised glass may fail under thermal stress.

6. Compliance & Standards

-

Meets ASTM E960 (lab glassware)

-

ISO 4797 (thermal shock testing)

-

CE marked for EU markets

Glass Funnel

Glass laboratory funnel. Its main characteristics are as follows:

Material:

Made of borosilicate glass, known for its resistance to saline solutions, acids, bases, and organic solvents, as well as thermal shock.

Construction:

It consists of a flared conical portion for easy pouring and a tubular stem to direct the flow into a narrow-mouthed container.

Use:

Mainly used for transferring liquids or powders into narrow-mouthed containers without spilling, and can also be used as a filter paper holder during gravity filtration.

Dimensions:

Glass funnels are available in various sizes, namely: 90mm, 120mm, with varying stem diameters and lengths, suitable for various laboratory applications.

Standards:

Manufactured according to specific standards such as ISO 4798 or DIN 12445 to ensure quality and laboratory compatibility.

Separating Funnel

The separating funnel has the following characteristics:

Shape:

It is pear-shaped (or conical), optimized for phase separation.

Materials:

Made of borosilicate glass, which gives it chemical resistance and inertness.

Capacity:

The marking on the funnel indicates a capacity of 500 mL.

Stopcock:

It is equipped with a PTFE (polytetrafluoroethylene) stopcock, known for its chemical resistance and leak-tightness. The stopcock allows precise control of liquid flow.

Ground Joint:

The upper neck has a 24/29 type ground joint, indicating compatibility with stoppers or other laboratory equipment of the corresponding size.

Conformity:

This type of funnel complies with international standards such as ISO 4800.

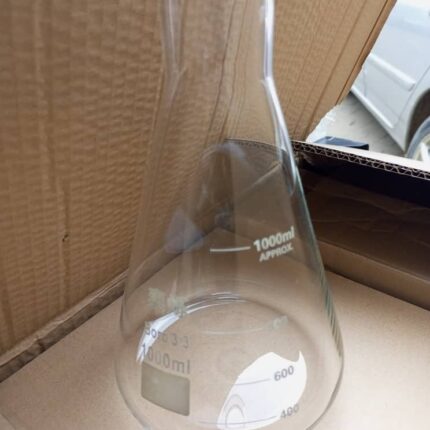

Erlenmeyer flask 1000 ml

A borosilicate glass Erlenmeyer flask has several key characteristics:

Materials:

It is made of borosilicate 3.3 glass (such as Pyrex™ or Duran®), known for its high resistance to thermal shock and chemical corrosion.

Capacity:

The flask pictured has a capacity of 1000 ml, with graduations indicating volumes (e.g., 400 ml, 600 ml).

Shape:

Its conical shape ensures good stability and facilitates mixing and heating liquids. The neck can be narrow or wide.

Graduations:

It has graduations (often white enamel) for approximate volume measurements.

Resistance:

Borosilicate glass provides excellent heat resistance, allowing direct heating and autoclaving for sterilization.

Use:

It is commonly used in laboratories for mixing, heating, cooling, and storing liquids, as well as for titrations and cell cultures.

Graduated Pipette

The characteristics of these graduated pipettes are as follows:

Brand and Volume:

This is a Citotest brand graduated pipette, with a maximum volume of 50 ml.

Materials:

It is made of glass, as suggested by its transparency and common laboratory use for this type of instrument.

Graduations:

The pipette features clear and precise graduations, allowing for accurate measurement of liquids.

Conformity:

Graduated pipettes of this type comply with the accuracy standards for laboratory volumetric instruments, such as the ISO 6706 Class B standard for graduated cylinders mentioned for similar Citotest products.

Use:

It is designed for transferring and measuring precise volumes of liquids in the laboratory, particularly for liquid handling.